Special Solutions

Below a selection of examples of special solutions.

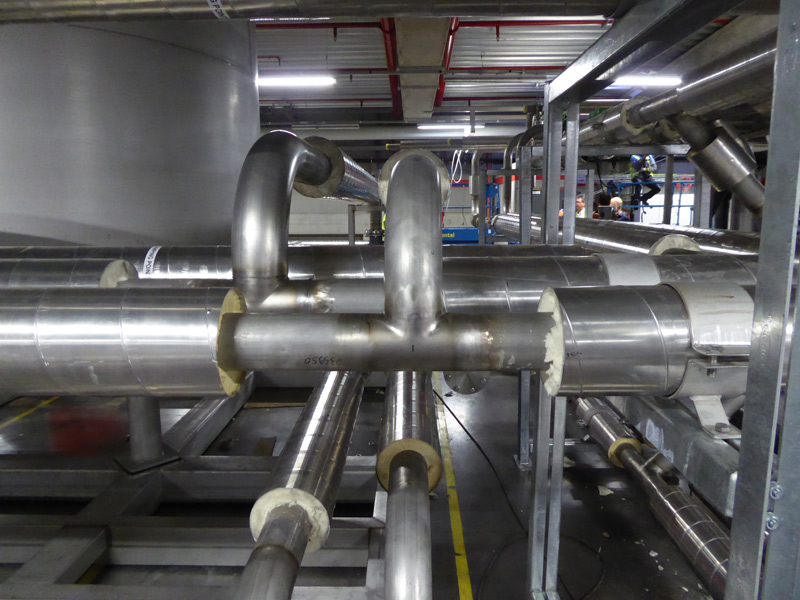

Different medium pipe dimensions had been installed in this project, starting with DN 25 up to the maximum of DN 200. A total quantity of 3,000 m had been realised with pre-insulated pipe system “RAPID EASY CUTTING“.

International Retailer, Belgium

In 2016 an international retailer insisted in the renewal of his ice treat- ment plant. This building measure was characterised by numerous short pipe sections with various multiple layouts. Dedicated for the application was System “RAPID EASY CUTTING“ which is due to the easy cut-to-length processing of this pipe system at site. A special coating facilitates the system for a residuefree dismantling of thermal foam insulation. An essential aspect for rating of working time and installation costs.

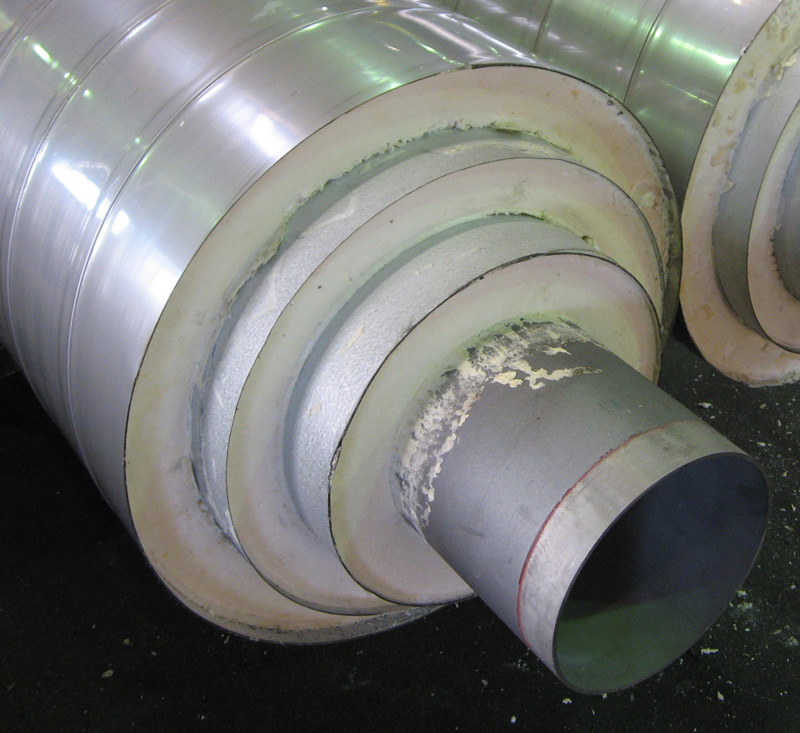

Fixed-points for industrial complexes processing LNG and ammonia

In 2017 more than 100 pre-insulated fixed-points made by Jabitherm Rohrsysteme AG were delivered for a LNG-project and an ammonia plant in Antwerp. These especially designed fixed-points for cryogen use completed the previous installations of pre-insulated pipes by Jabitherm Rohrsysteme AG and mirror the same design concept: Medium pipe – PU foam insulation – outer protective jacket

The engineering design of these fixed-points in conjunction with a significantly increased polyurethane foam density provides extreme force balance.

An important safety aspect for pipe installation!

The engineering design of these fixed-points in conjunction with a significantly increased polyurethane foam density provides extreme force balance.

An important safety aspect for pipe installation!

Installations with FIRESAFE® pre-insulated pipes for hazardous or/and potentially inflammable areas can be completed with fixed-point fulfilling the same process requirements. According to the pipe format the thermal insulation inside is double- or triple-layer.

So it realises together with the pipe fire protection up to 90 minutes. (T-rating: T30, T60 and T90) The combination of both, cryogen operating condition and fire protection in one, were finally the crucial arguments for use in both projects.

So it realises together with the pipe fire protection up to 90 minutes. (T-rating: T30, T60 and T90) The combination of both, cryogen operating condition and fire protection in one, were finally the crucial arguments for use in both projects.

The scope of application covers at site transferring lines for potable and industrial water and with main focus on carriage of LNG between disembarking from LNG tanker to LNG storing tanks.

The pipes transfer the liquid natural gas at operating tempe- rature of around -163°C. These circumstances put focus on the solution for connecting fixed-points to pre-insulated pipes.

Significant for the fixed-point design are plain face ends and circumferencial metal sheath which enables connection to adjacent pipe ends with standard joints. An integrated system self-obviating ice formation.

The pipes transfer the liquid natural gas at operating tempe- rature of around -163°C. These circumstances put focus on the solution for connecting fixed-points to pre-insulated pipes.

Significant for the fixed-point design are plain face ends and circumferencial metal sheath which enables connection to adjacent pipe ends with standard joints. An integrated system self-obviating ice formation.